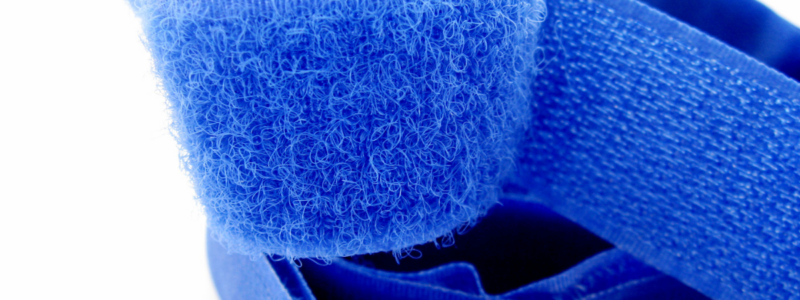

Self-adhesive Hook and Pile fasteners with an acrylic adhesive layer is mainly used in humid conditions, more extreme temperature differences or materials such as plastics. This Hook and Loop Adhesive Acrylic Loop is “Ready-to-Use” and “Pressure Sensitive” which means that the Velcro can be easily cut to the desired length with scissors. And after removing the protective film, the self-adhesive Hook and Loop fasteneres can be applied directly by hand.

High quality acrylic Hook and Pile fasteners

The Touch fastener closure is also of high quality and has a high closing force. The starting point is a premium quality Touch fasteners made of 100% nylon and good for 10,000 openings.

The acrylic adhesive layer has a high adhesive force on materials such as wood, metal, glass.

This adhesive layer is protected by a foil. This can be a PET film or a cardboard/paper film; also called Pet film release or Paper release. The type of protective film may be a preference for some users; the adhesive layer and the Touch fasteners remain the same.

From stock, Self-adhesive Hook and Loop Acrylic Loop is available in 7 widths in black and white in 25-meter rolls.

Characteristics of self-adhesive Velcro with an acrylic adhesive layer

– High adhesive strength; (almost) immediately ready for use after application

-Temperature range -200°C – 120°C

– Acrylic adhesive layers can be used in humid conditions, but are not a durable solution with regular direct contact with water.

In addition to Hook and Loop fasteners with an acrylic adhesive layer, we also supply Hook and Loop fasteners with a Hotmelt adhesive layer and weldable Touch fasteners. Need more information about which adhesive layer is suitable for your application? Read the information about self-adhesive Touch fasteners or contact us.

Application instructions for self-adhesive Hook and Pile fasteners with an acrylic adhesive.

– Clean the surface from dirt, dust and grease

– The surface must be smooth and even. With a rough, irregular surface, air can get behind the adhesive layer.

– Process the product preferably at room temperature; extreme temperatures can affect adhesive strength

– Apply by hand and press well. Pay extra attention to pressing the edges.

– The product is ready to use, but preferably let the adhesive layer cure for 48 hours for the best possible adhesive strength